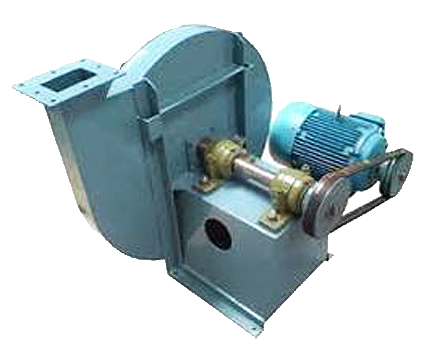

Centrifugal Blower

Centrifugal blowers use high speed impellers or blades to impart velocity to air or other gases. They can be single or multi-stage units. Like fans, centrifugal blowers offer a number of blade orientations, including backward curved, forward curved, and radial.